Our NDT Inspection Service uses advanced techniques to detect material defects, ensuring safety and reliability across industries without causing damage to the components.

Non-Destructive Testing (NDT) inspection services utilize advanced techniques to assess material integrity without causing damage. These services play a crucial role in industries such as aerospace, automotive, construction, and manufacturing by detecting defects, ensuring safety, and maintaining quality standards. NDT methods include ultrasonic testing, radiography, magnetic particle testing, penetrant testing, and visual inspection, each tailored to specific materials and applications. NDT inspections are essential for preventing failures, reducing downtime, and optimizing asset lifespan, making them indispensable in modern industrial practices.

Penetrant testing utilizes capillary action, where a liquid rises or climbs in small openings due to its surface wetting properties. This method effectively detects surface-breaking discontinuities on smooth, nonporous surfaces. It is particularly suited for inspecting parts with complex geometries. Indications of defects are visible directly on the part’s surface, providing a clear visual image of any anomalies detected.

Magnetic Particle Testing (MT) is a versatile inspection method used for detecting surface and near-surface defects in ferromagnetic materials, suitable for both field and shop applications. The process involves magnetizing the specimen using a magnet or specialized equipment. Discontinuities in the material disrupt the magnetic field, creating leakage fields. Finely milled iron particles coated with dye are applied to the specimen and attracted to these leakage fields, clustering to form visible indications of defects under proper lighting conditions.

Ultrasonic inspection, commonly performed on steels and metals, can also be used successfully on non-metallic materials. This non-destructive testing method is widely used in industries such as aerospace, automotive, pressure vessels, and welding fabrication. It effectively locates subsurface discontinuities in weldments, even with access to only one side. Key advantages include high penetrating power for thick parts, high sensitivity for detecting small discontinuities, requiring access to only one surface, being non-hazardous to operators and nearby personnel, and high portability.

Visual inspection forms the foundation of all NDT inspection programs. At Alpha Inspection Solutions, we offer a comprehensive range of visual inspection techniques (VT) conducted by certified Welding Inspectors (CSWIP) across various industries, including Oil and Gas, Nuclear, and Power Generation. Additionally, our center of excellence in turnaround management provides staffing and oversight for Oil and Gas maintenance turnarounds, ensuring optimal performance and safety.

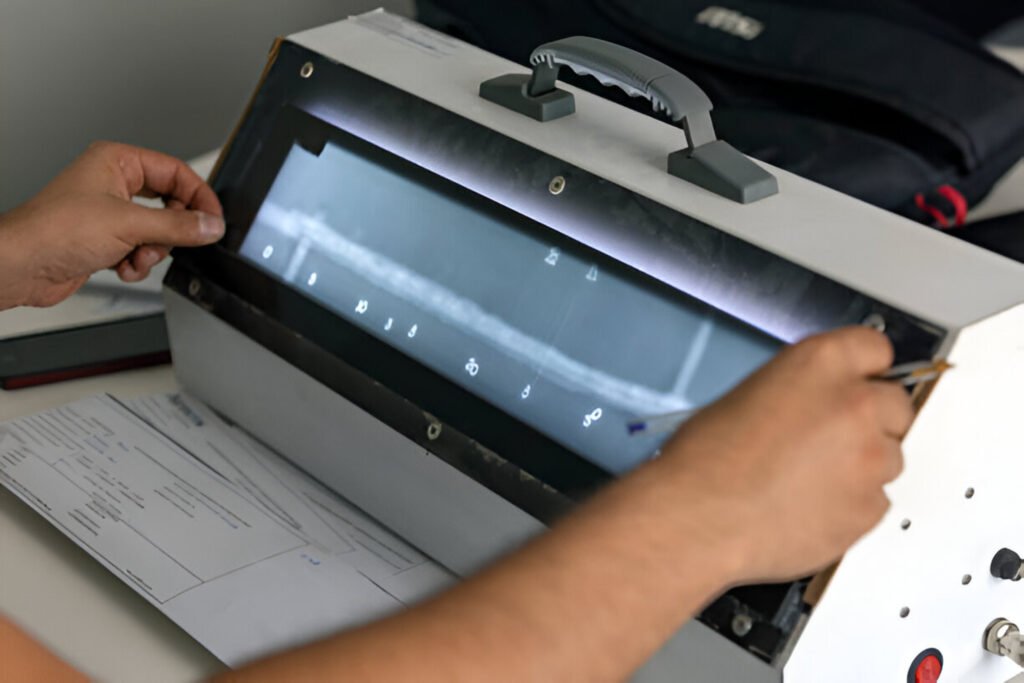

Radiographic weld inspection is a critical method in non-destructive testing used across various industries. When a discontinuity is detected in a weld, the radiographic interpreter assesses the radiographic images according to the specific criteria outlined in the applicable code or standard. This evaluation determines whether the discontinuity qualifies as a defect requiring remediation or is considered an acceptable condition within the parameters set by the code. This process ensures the integrity and safety of welded structures in demanding applications such as aerospace, automotive, construction, and more.

Working with Alpha NDT Training Center has been a game-changer for our construction projects. Their welding inspection services are meticulous, and their reports are always comprehensive and clear.

Client

Alpha's expertise in painting inspection has been invaluable to our heavy machinery maintenance. Their team's professionalism and attention to detail have significantly improved our operational efficiency.

Client

We rely on Alpha NDT Training Center for all our third-party inspections. Their unbiased and precise assessments ensure we meet all industry standards and regulations, making them an essential partner for our petrochemical projects.

Dedication to excellence in both education and industrial services, bridging the gap between learning and practical application

Copyright © alphandtcom. All rights reserved.

Prasad Neyyila

Client